M-Line Blog

A Guide to Choosing Foam Packaging

Foam can be an excellent option for protecting products in transit, and for creating a perfect custom fit within a plastic case, box or crate.

There are a variety of foam options to meet your needs. Learn more by watching our video or reading on.

4 Types of Foam Packaging to Protect Products in Transit

-

Expanded Polystyrene (EPS) - This type of foam is fairly rigid, and is mainly used for blocking and bracing. It can also be molded. It’s the least expensive foam option, especially when molded in high quantities, although the molds themselves can be expensive. EPS is brittle and prone to cracking.

-

Polyethylene (PE) - PE is fabricated from foam planks, usually either 1, 2 or 3 inches in thickness. It’s a common choice for cushioning and vibration dampening. It’s also available in a variety of colors. The price is usually slightly higher than EPS.

-

Polyurethane (PU) - Polyurethane has a sponge-like feel, making it excellent for vibration dampening. It comes in a variety of colors as well as different densities. PU also has a slight sparkle, which varies depending on the grade. It’s commonly used as a case insert.

-

Crosslinked Polyethylene (XLPE) - Crosslinked polyethylene is the Cadillac of packaging foam. Its smooth feel and density make it perfect for protecting highly-polished surfaces or Class-A surface protection. It’s available in various colors and is great for waterjet cutting, as it doesn’t absorb water. It’s also the most expensive foam option.

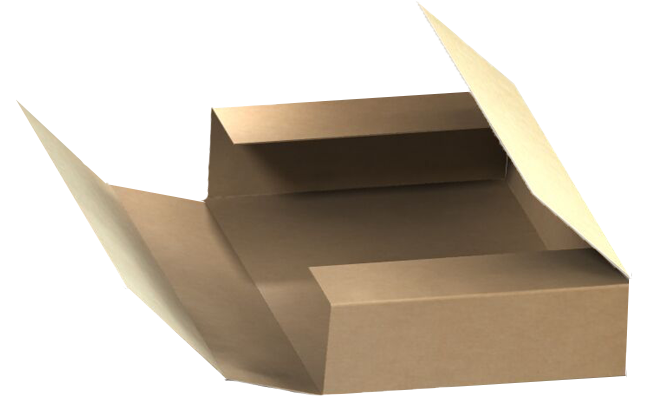

Packaging foam is a great option to pair with a custom box for a perfect product fit.

Which Foam is Right For My Product?

The right foam for your product will depend on a variety of factors. As you evaluate different options, you’ll need to consider the following:

- Is the final appearance of my product important? Class-A surfaces and other products need to look their best when they arrive and might need a foam with superior protection.

- How heavy is my product? A very heavy product might not be suited for foam like expanded polystyrene, which could crack easily.

- How large is my product? Similarly, consider whether your product ships by itself in a large box or with multiples.

- What is my budget? XLPE foam is top-notch, but it’s expensive. Do you really need it, or would a cheaper option work?

- Should the foam be reusable? Durable types of foam can be used over and over again. Other types are best for a single use.

- How will my product ship? Is it being transported via truck, parcel service, air, boat or drone?

- How shock-resistant is my product? Is it sensitive to vibration and movement? How fragile is it?

- What should the unboxing experience be like? What do you want your customer (or the end-user) to see when they open the box?

- How important is sustainability? Are you considering a disposable product, or one that is recyclable or reusable?

Use these questions to help you get started, and contact a packaging expert to ensure you get the best packaging for your needs.

Get the Foam Comparison & Pricing Chart

Download our free foam comparison guide to see a handy chart comparing each type of foam side-by-side. You’ll also get sample prices per piece to help you start an estimate today!