M-Line Blog

Product Packaging Project Timelines: What to Expect at Every Stage

A significant packaging project has just been assigned to you for a brand-new product, and top management has high expectations for its market success. Your first decision is whether to handle it in-house or outsource it to a custom packaging company. Previous attempts to in-source packaging projects fell short due to resource constraints and other issues. However, you've received positive feedback about M-Line, a custom packaging solutions company.

M-Line to the Rescue

You contact M-Line and inform us that the new product is in the prototype stage or nearly ready for launch. We ask relevant questions about the product's nature, weight, fragility, and other characteristics, as well as request pictures and product files, particularly a 3D STEP file. This file allows us to examine the product simulation from every angle to capture critical dimensions. Ideally, we prefer both a 3D STEP file and a sample of the product, as seeing it often highlights fragile areas.

Next, we inquire about your target market. Are you shipping medical devices to a hospital or a patient's home? Each scenario presents unique challenges, such as ensuring the package fits through doorways or up staircases. We also ask about the shipping cycle: Will the product be shipped on a pallet via truck or through parcel service?

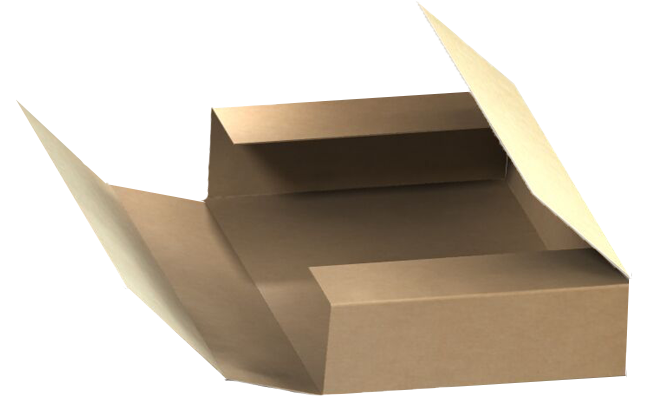

M-Line needs to understand your branding campaign as well. Do you want to ship the product in a plain box to conceal its value or make a brand statement with the packaging? How will the box be used? Will it store the product after use? Finally, we ask about expected shipping volumes. Shipping hundreds of thousands of products annually opens up different packaging options compared to only shipping a few hundred.

Project Timeline: Where the Rubber Meets the Road

The design time for a typical project is three to five days. M-Line may send you an initial concept for feedback and follow up with a quote a few days later. If you approve the concept and it's within budget, we will develop a prototype within one to two weeks plus shipping time. Once you place an order, production typically takes three to four weeks plus shipping time. Customer changes can extend this timeline depending on modifications, highlighting the importance of providing accurate information at the project's outset to prevent delays.

If desired, M-Line can perform official International Safe Transit Association (ISTA) shipping tests on the packaged product. Many companies have their own approaches to shipping tests, and M-Line is often called upon to "fix" packaging designs that have failed during testing.

Ergonomics also play a crucial role in packaging design. For example, when dealing with heavy products that require users to bend over for extraction, M-Line might design the box in two halves to minimize bending and lifting.

To learn more about M-Line's packaging project timeline, call (800) 659-8669 or request a quote.

Contact us to learn more.