M-Line Blog

Kitting and Packaging: How to Save Time and Money

Ordering, organizing, and putting together your packaging can take a lot of time and money. That’s time and money you’d probably rather spend elsewhere.

One solution is kitting, which shifts the work of putting together complex packaging off your shoulders. Read on to discover more about kitting and how it can benefit you and your business.

What is Kitting?

With kitting, M-Line takes care of procuring and assembling all of your necessary packaging materials. Instead of ordering many individual parts, you just order one - and we put it together for you. Once the kit is delivered, you can simply add your product and prep it for shipping.

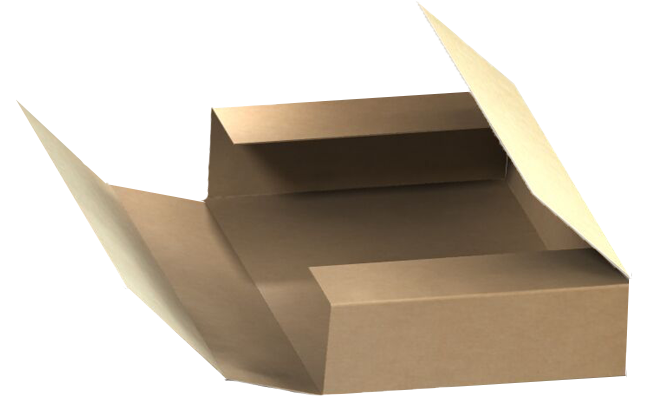

Take the example of the picture here. Normally, each of the items inside the crate would have to be pulled off a pallet, assembled, and put back inside the crate. That means you would need employees to do all of these tasks and the warehouse space to do it.

By choosing kitting, you can free up that space and labor for other tasks at your company

What are the Benefits of Kitting Packaging?

Here’s what’s usually involved in putting together your own packaging for a complex crate:

- Pull out all of the skids of the product that you need, and then take the correct number of parts that you need from each pallet.

- Transport the parts to an assembly area where you would stitch the trays, tape the boxes, and insert the foam.

- Gather the correct combination of items together that go in each crate.

- Pack all of the items into the crate.

When we put the packaging together for you, you save time and money and enjoy additional benefits such as:

- Reduced warehouse space needed to store packaging

- Savings on assembly labor

- Ability to order just one part number instead of multiples

- Having the right count of parts on hand instead of overruns, underruns and shortages

- Receiving the kit as you need it on a JIT basis. The kit can arrive and go straight to your assembly station where you put your product inside, then go directly to the shipping area. There’s no warehouse space needed.

Real-Life Example: Kitting Saves Customer Thousands

Madrigal Company* was building their own crates in-house for their equipment, with two full-time employees cutting wood, building crates, and inserting foam.

M-Line identified an opportunity to modify the method for packaging and provide the customer with just-in-time delivery of kitted packaging. Madrigal received the new packaging as needed, placed their items inside the kitted packaging, and shipped the product.

Per M-Line’s suggestions, the two employees previously required to complete these tasks were relocated to manufacturing, reducing the company’s packaging budget by $80,000. JIT delivery provided additional savings by reducing space on the customer’s floor and improving cash flow, as packaging was not purchased or received until needed.

Need Packaging Help? Let M-Line Take Care of It

M-Line can help solve your biggest packaging headaches. From design to warehousing to delivery, we can streamline your processes and help you get your time back.

Interested in learning more? Request an audit! We’ll take a look at your packaging process and let you know where you could save time and money.