M-Line Blog

8 Ways a Packaging Distributor Can Help You in 2022

In these current economic conditions, working with a packaging distributor can be more valuable than ever. With long lead times, inflation, and labor shortages, working with a distributor can make your life a whole lot easier — and also save you a lot of money. Here are eight reasons to consider working with a distributor for your packaging needs.

1. Reduced lead times

To counteract long, unpredictable lead times, you can place a blanket order for your packaging items with a distributor who can stock your product and release it to you as needed. A good packaging distributor will manage the production lead times for you and notify you when you should place your next order.

2. Lower prices

A packaging distributor can switch you to another manufacturer’s comparable product, design an alternative cost-effective solution, and warehouse larger production runs to take advantage of a quantity price break

3. Warehouse Labor Problems — Solved

These days, it seems everyone is having trouble finding labor. If you are short-staffed, a good packaging distributor can help.

Short on warehouse personnel? A packaging distributor can control the flow of packaging into your company to make it easier for the staff that you do have. That could mean more frequent or less frequent deliveries. Additionally, your product could be supplied in a kitted form instead of individual pieces on multiple pallets.

You could also let your packaging distributor manage your inventory by setting up a vendor-managed inventory program

And finally, there may be areas where automation could be implemented with automated tape applicators, void fill machines, stretch wrap equipment, strapping tools, etc. All of these things will allow your warehouse staff to work more efficiently or spend time on other tasks.

Read more about how we can help solve labor challenges >

4. Fewer Truck Delays

A good packaging distributor has a fleet of trucks to deliver products to your door. In these current economic conditions, commercial freight lines are over capacity. They are short on drivers and deliveries are commonly delayed

When your packaging product is in a distributor’s warehouse, it just needs to be loaded on the distributor’s truck and quickly get to your dock.

5. Fewer Import Bottlenecks

If you import some of your packaging materials, your container costs have probably gone up 4 times in the past year. You are also waiting a LOT longer to get your imported product because the containers have been stuck at sea waiting to be unloaded at the docks

Having your item produced domestically may make more sense. A good packaging distributor has the appropriate relationships to get your product manufactured at a competitive price and reduce that long import lead time.

6. Vendor Consolidation

If you’re cutting multiple purchase orders to multiple vendors, a packaging distributor can be a one-stop-shop by combining all of your packaging suppliers into one. All of those purchase orders that cost on average $110 to cut, can be reduced to a much smaller number by going with one vendor

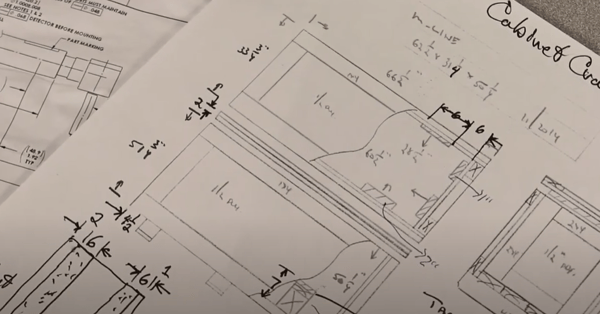

7. Engineering Services

Are your engineers spending time attempting to develop packaging when they should be spending time on your company’s core competency? A good packaging distributor will have engineering on staff to work alongside your engineering department

The packaging engineer can create a design out of multiple materials, supply prototypes from their in-house design lab, and provide the appropriate files and documentation to supplement your quality system that is already in place. You should continue to have your engineers working on your products, not your packaging.

8. Graphic Design Services

Need help with your branding? Art files? Printed prototypes? A great packaging distributor will have a graphic design professional on staff as well as a print design lab with digital printers for prototyping and short-run production.

Learn More About Our Services

Not sure if a packaging distributor is right for you? Learn more about the services we offer and see how the process works.